Post Installation Maintenance Advice (O&M manual) and care of finishes

Maintenance Advice

To ensure the reliable operation of an ironmongery component, it is important that the manufacturer’s installation instructions are followed. Furthermore, since a building's hardware will be subject to varying levels of use throughout the working week, it is important that these fittings are routinely inspected to check that they function correctly. They will also need to be maintained and adjusted to counteract the wear and tear of their operational lives in accordance with the manufacturer’s recommendation. Suggested routine maintenance guidelines are detailed below. These should be read in conjunction with the information supplied with the product. Following installation it is important that any fixing/maintenance instructions are retained and passed on to the Building Manager / Maintenance Department for future reference.

The following guidelines are of the upmost importance with regards to the operation of any fire check items and fire escape hardware. People‘s lives could be endangered by incorrectly fitted and/or poorly maintained hardware.

Hinges

It is important that the correct hinge is fitted taking into account the door’s size, weight and purpose e.g. FD30, FD60, etc. (see pages 10 and 11 for further details).

When fitted it is important that all of the hinge knuckles, or more precisely, the hinge pins are vertically aligned on a particular door. This is to ensure that the axis of rotation of the door lies on a common centreline parallel to the edge of the door and frame. Misaligned hinges will distort the rotational axis leading to undesirable stresses on the hinge, their fixing screws, the door and its frame. Consequently both hinge and door performance will be impaired and hinge wear increased. If a door's hinges regularly work themselves loose or they continually squeak, then hinge misalignment should be investigated.

Newly fitted hinges containing ball bearing races packed with grease may experience a small amount of grease seepage following installation. Any excess grease is expelled from the bearings as it beds in. The grease should be wiped from the hinge knuckle using a cloth moistened with white spirit or suitable degreasant.

Self lubricating hinges (see page 10) are available which are effectively maintenance free with regards to lubrication. This is achieved by the use of flanged bushes that have been impregnated with a specially formulated lubricant.

Locks and Latches

The most important factor in obtaining optimum lock performance is correct fitting. The lock should be fitted perpendicular to the edge of the door with its faceplate flush to the edge.

The position of the strike plate is important because it must receive the lock bolts cleanly without any snagging. It is also important that the space behind the strike plate is morticed deep enough to allow free operation of the lock bolts. Typically the gap between door and door frame should be 2-3mm (always confirm with door manufacturer).

Routine inspection of locks should ensure that they engage their strike plates correctly, otherwise lock bolt snagging may arise. Causes of snagging include movements in the door and frame due to climatic changes, hinge wear or even the presence of debris in the strike plate mortice. Lock binding is clearly undesirable and could potentially lead to the door jamming closed.

Fixing screw tightness should also be checked. A small amount of lubricant can be applied to the side and striking face of the latch bolt to facilitate its smooth operation. Excess lubricant should be wiped away to prevent its transfer onto clothing during routine door operation.

The internal mechanisms of key operated three and five lever locks and cylinder lock cases are well greased by the manufacturers and consequently do not require further maintenance.

Cylinders

The cylinder keyway should be sparingly lubricated when required with a specialist lock lubricant. The use of standard oil lubricant should be avoided as these comparatively viscous oils can attract and hold dust. This could eventually lead to a clogging of the keyway and/or the cylinder pins.

Lever Handles

Poorly fitted handles can hamper a lock function by causing the latch bolt to snag. It is therefore important when fitting the handles to ensure that the spindle and lock follower are properly aligned. Following fitting, the handle fixings should be periodically checked for tightness. This includes any grub screws that hold the spindle securely within the handles. Tight fixings take on additional importance if a door closer is fitted.

Pull Handles

Pull handle fixings should be tightened when necessary as loose handles will become progressively more unstable with continued use. They may even be pulled off the door completely if it is opened sharply, as may be the case in a panic situation. As with lever handles, tight fittings take on an additional importance if a door closer is fitted.

Overhead Hydraulic Door Closers

It is important that all door closers are fitted accurately, following the manufacturer’s instructions and using the template supplied. They should also be correctly adjusted with respect to the closing speed and latching action to ensure that the door closes properly and overcomes any resistance encountered, e.g. as a result of smoke seals or a latch bolt being fitted. Slamming of the door should be avoided as this may leave the door slightly ajar. Changes in ambient temperature and humidity can also affect door closer performance as a result of door and frame expansion. These temperature changes may also cause variations in the viscosity of the hydraulic fluid contained within the door closure mechanism. Consequently the need may arise for door closer speed and latching action to be adjusted. More sophisticated door closers may also have backcheck and delayed action functions which should also be adjusted when required to ensure satisfactory door operation.

Since hydraulic door closers are factory sealed units they should be periodically inspected for any sign of leakage after fitting.

The smoothness of the closing action of the door will be affected if:

- the screws holding the unit to the door and/or frame work loose

- the fixing bolt holding the arm to the mechanism works loose

- the pivot point of the arm is poorly lubricated resulting in unwanted frictional forces

It is therefore important that these areas are addressed during routine door closer maintenance.

Powermatic and Perkomatic Door Closers

These are factory sealed hydraulic units that should be inspected for any signs of leakage or closing chain/linkage damage. The chain should also be kept lightly greased to minimise any frictional forces. The latching speed needs to be properly set to ensure door closure without slamming. The fixing screws into the door and frame should also be checked for tightness.

Concealed Overhead Hydraulic Door Closers

These units should be adjusted as necessary for closing speed and latching action. The smoothness of travel of the arm along its channel also needs to be checked. Since these closers are housed within a cavity in the top of the door, careful inspection around the pivot seal should be carried out to ensure that no hydraulic fluid leakage is occurring from the unit as this will not be as self evident as with a surface mounted mechanism.

Floor Springs

When fitting a floor spring it is important that the mechanism is accurately positioned in the floor. This is to ensure that when the unit self centres it is properly aligned with its frame (or mirror image in a double door set). Misalignment may prevent the proper engagement of fire and smoke seals.

Similarly to other hydraulic door closers it may be necessary to adjust the closing speed and latching action controls of the floor spring mechanism. Any debris that has accumulated in the vicinity of the spindle should also be periodically removed. Signs of hydraulic fluid loss should be looked for around the pivot seal and in the bottom of the floor spring housing box. The bolts holding the mechanism down and the screws securing the top centre and bottom strap should all be tight. The top centre also needs to be carefully inspected for any signs of wear.

Electro-Magnetic Door Closers, Floor Springs & Hold Open Devices

These door closers and floor springs should be adjusted as described above. In addition, the closing action of all electromagnetic hold open devices should be regularly checked in conjunction with the activating alarm or sensor system to ensure correct operation and that no residual magnetic fields impede the onset of the door closing. It is recommended that such checks are carried out on a weekly basis.

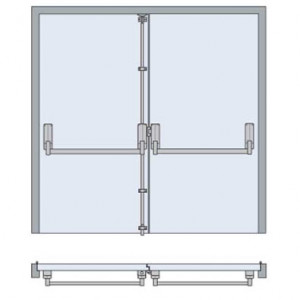

Panic Hardware

For safety it is essential that all fire escape and panic hardware is fully functioning at all times. Regular inspection and servicing of these devices is therefore very important.

Ease of use must be ensured at all times with any necessary adjustments being made to compensate for door and frame movement. Components should be inspected for signs of wear and tear, misuse or vandalism. Moving parts should be lubricated with a light machine oil when required. All fixings screws need to be securely tightened. The operating bars and rods should be checked for straightness and floor sockets should be cleaned out if they have accumulated any debris.

Fire & Smoke Seals

These need to be inspected periodically to ensure that they are unbroken and are securely fixed within the door leaf. It is also important to check that the gap between the door and frame is effectively closed by any smoke seals fitted.

Damaged or worn seals should always be replaced. Ensure that at no time these strips are painted as this will cause them to harden and lose their ability to perform.

Care of Finishes

Stainless Steel

All internal, external and exposed surfaces require regular cleaning (dependent upon usage and environmental conditions) with a soft cloth, using warm water and mild detergent to remove built up dirt and grime.

Surface oxidation can appear as a result of contaminants, this is known as flash rust. For removal, clean with a cloth and warm water, ensuring surface is dry before applying a specialist stainless steel cleaner.

The use of steel wool and steel brushes should be avoided as tiny breakaway particles may become embedded in the surface, which can lead to a rust staining.

It is recommended that routine cleaning is undertaken on a monthly basis and in areas of extreme environment or contaminants this should be increased accordingly.

Brass

Lacquered brass should be regularly dusted with a soft cloth. To prolong the life of lacquered brass it is advisable to regularly clean the item using a cloth moistened with soapy water (pH Neutral). The occasional application of a good quality wax polish will also help to seal chips and scratches in the lacquer itself.

In exposed and external situations, more regular waxing is advised to keep it clean. Eventually it is possible that the lacquer will deteriorate beyond your maintenance capabilities. When this occurs, all traces of the lacquer should be removed using an acetate lacquer remover and polished back to its original finish using a good quality brass cleaner. Once the lacquer has been removed, it is advised not to re-lacquer but to regularly clean as un-lacquered brass.

To keep un-lacquered brass in a polished state you will need to clean it with a high quality metal cleaner. Indoor pieces such as door handles, knobs and hooks will need a polish 3-4 times a year or more often if the piece is regularly handled. Exterior pieces such as your door knocker and letter plates will need doing monthly to keep them in a high shine.

Aluminium

Anodised aluminium is extremely durable as the anodising process helps to harden and coat the metal. As a result, this process creates a weather-resistant, tarnish-resistant surface that can remain like new for years, but over time anodised aluminium will begin to naturally scratch and fade like any other metal.

To offset these effects it is advisable to clean the exposed surface periodically with a soft damp cloth, using warm water and mild detergent to remove the build-up of dirt and grime.

Abrasive metal polishes should not be used as this may damage the anodised layer.

Powder Coated and 2K Sprayed Finishes (With or Without Antimicrobial Additive)

All external and exposed surfaces require regular cleaning with a soft cloth and warm water to remove built up dirt and grime. After each and every clean, wipe down products with a separate clean dry cloth.

For exposed items and regularly handled products applying a quality automotive wax product has been found to prolong the finish.