Hinge guide & BS EN 1935 Classification

A Brief Guide to Hinges

Factors to Consider

- Is it a fire, smoke or emergency escape door?

- The size and weight of the door?

- Is it an internal or external door; is it near the coast or in a swimming pool?

- Is it to be used in an office environment with minimal use or for higher volume traffic such as a hospital, school or shopping centre?

- Is there any other door hardware to be fitted that may affect performance (ie door closer, door stops).

Forces Operating on a Door

There are two main forces that the hinge has to cope with. The vertical load; and, as hinged doors are sidehung, the horizontal or lateral load.

- The vertical load is a direct result of the gross door weight.

- The horizontal load is created by:

- The door weight

- The door height to width ratio

- Where the hinges are positioned.

The wider the door is in relation to its height, the greater the side load that the hinges and their fixings have to support.

Adjusted Door Weight

Hinge specification is also determined by the adjusted door weight. We recommend wherever possible to refer to the actual weight supplied by the door manufacturer.

Adjusted door weight calculation table |

||||

|---|---|---|---|---|

| Actual door weight |

|

= Adjusted door weight | ||

|

||||

|

||||

|

||||

Locating the Hinges

- It is usual for at least three hinges to be fitted on doors; their positioning is determined by the size, weight and construction of the door and its intended use.

- The most common fixing positions are shown here:

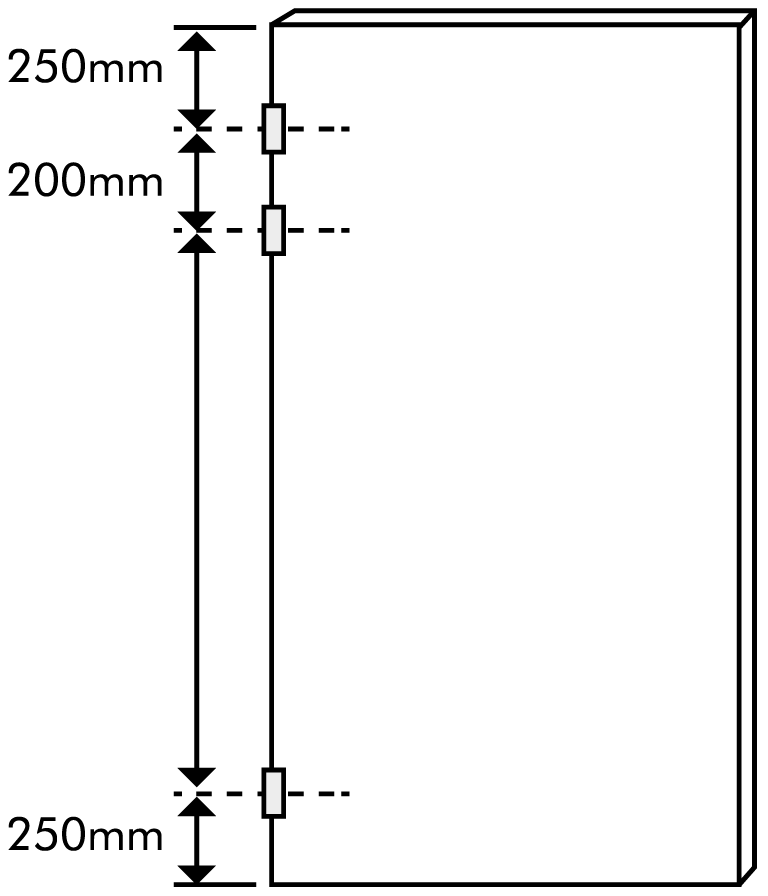

Fig.1

Standard Doors

The standard positioning when fitting three hinges to a door. This gives the most effective load bearing capability.

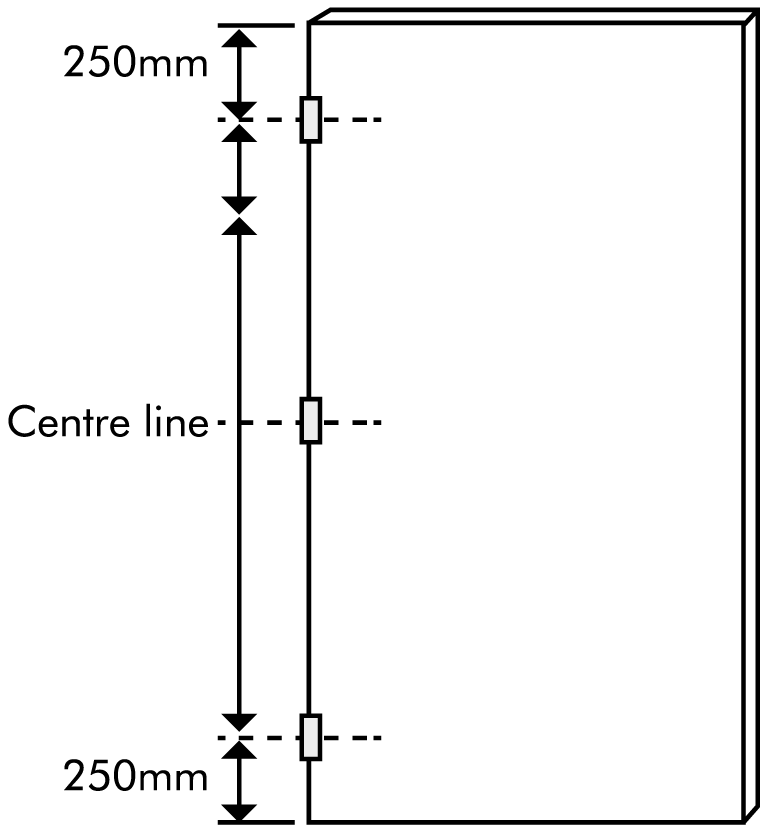

Fig.2

Lightweight Doors

Three hinges may be fitted as shown. On doors subject to warping (such as glazed doors), fit a third hinge at the centre of the door.

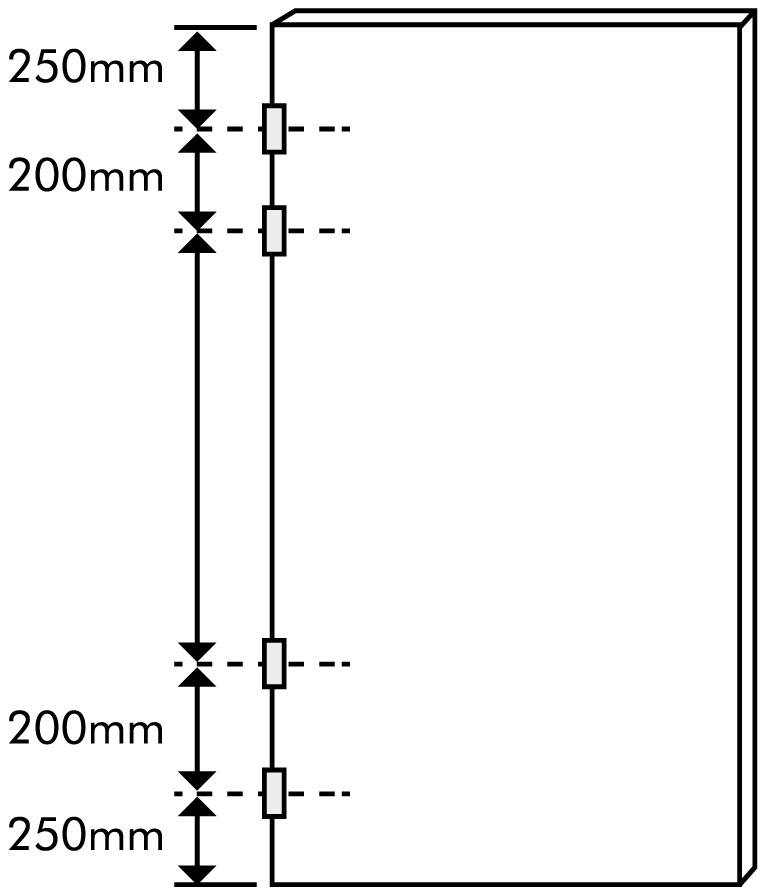

Fig.3

Heavy Doors

When load bearing is the prime consideration, fit four hinges as shown.

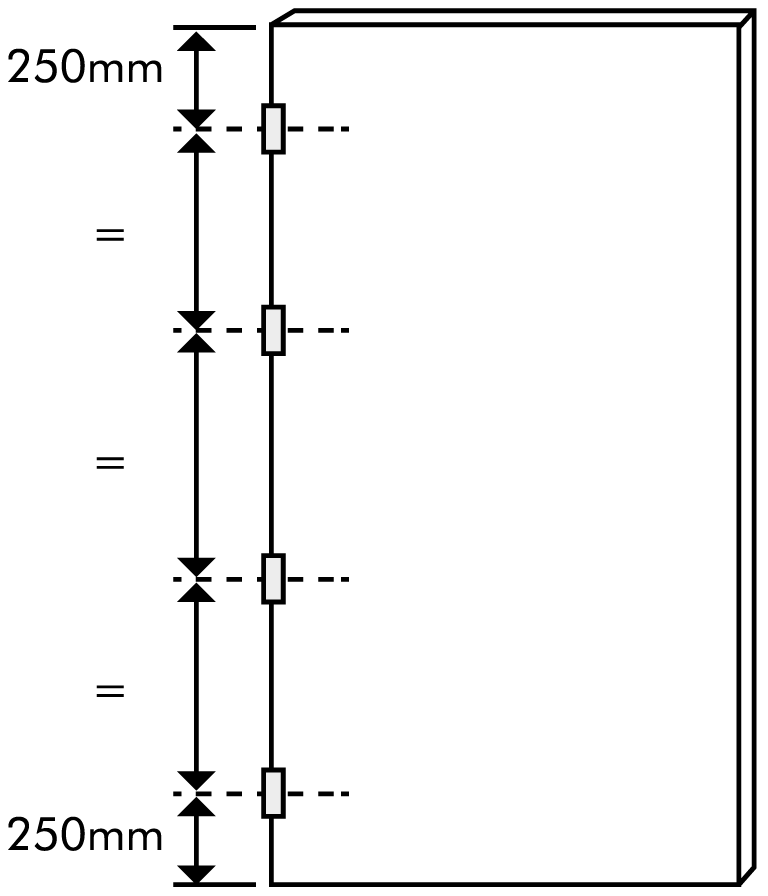

Fig.4

Tall Doors (Over 2100MM)

On all door or those which are particularly subject to warping (such as glazed doors) fit four hinges equally spaced, as shown.

Hinges for use with doors of excess widths

Wider doors obviously increase the pressure and bending moment exerted on the hinge. This must be allowed for by reduction in the maximum mass of the door leaf supported by each grade of hinge.

The factors by which the door mass has to be adjusted for excessive widths of door are calculated by dividing the door height by its width. For a factor of 2 or greater, no allowance has to be made. When the factor is less than 2, the door mass has to be increased by the value required to bring the factor to 2 expressed as a percentage. These percentages are shown in the side loading calculations table shown here.

SIDE LOADING CALCULATIONS |

|||

|---|---|---|---|

| Door Size | Factor | Normal increase of mass of door leaf % | |

| Door Height mm |

Door Width mm |

||

| 2000 | 1000 | 2.0 | 0 |

| 2000 | 1050 | 1.9 | 10 |

| 2000 | 1100 | 1.82 | 18 |

| 2000 | 1150 | 1.74 | 26 |

| 2000 | 1200 | 1.66 | 33 |

| 2000 | 1250 | 1.6 | 40 |

BS EN 1935 Single axis hinges

BS EN 1935 classifies hinges by using an 8 digit coding system.

A similar classification applies to all building hardware product standards so that complementary items of hardware can be specified to, for instance, a common level of corrosion resistance, category of use, etc. Each digit refers to a particular feature of the product measured against the standards performance requirements.

Digit 1 – Category of use

Four grades are identified:

- Grade 1: light duty

- Grade 2: medium duty

- Grade 3: heavy duty

- Grade 4: severe duty

Digit 2 – Durability

Three grades are identified for single-axis hinges:

European Standard

- Grade 3: 10,000 test cycles, for light duty hinges on windows only

- Grade 4: 25,000 test cycles, for light duty hinges on windows and doors

- Grade 7: 200,000 test cycles, for medium, heavy and severe duty hinges on doors only

Digit 3 – Door mass and closing force

Eight door mass grades related to single-axis hinges are identified in the European Standard as shown below:

| Test Door Mass Grade | Door Mass |

|---|---|

| 0 | 10kg |

| 1 | 20kg |

| 2 | 40kg |

| 3 | 60kg |

| 4 | 80kg |

| 5 | 100kg |

| 6 | 120kg |

| 7 | 160kg |

Digit 4 – Fire resistance

Two grades are identified for single-axis hinges:

- Grade 0: not approved for use on fire/smoke door assemblies

- Grade 1: suitable for use on fire/smoke door assemblies tested to BS EN 1634-1 etc

Digit 5 – Safety

Single-axis hinges are required to satisfy the essential requirements of safety in use. Therefore, only one grade is identified.

Digit 6 – Corrosion resistance

Five grades of corrosion resistance are identified in accordance with EN 1670:

- Grade 0: no defined corrosion resistance

- Grade 1: mild resistance

- Grade 2: moderate resistance

- Grade 3: high resistance

- Grade 4: very high resistance

Digit 7 – Security

Two grades are identified for single-axis hinges:

- Grade 0: not suitable for burglar-resistant door assemblies

- Grade 1: suitable for applications requiring a degree of security

Digit 8 – Hinge Grade

Fourteen grades are identified in this European Standard and are listed below:

| Hinge Grade | Usage | Test Cycles | Door Mass |

|---|---|---|---|

| 1 | Window | 10,000 | 10kg |

| 2 | Window | 10,000 | 20kg |

| 3 | Window/Door | 25,000 | 20kg |

| 4 | Door | 200,000 | 20kg |

| 5 | Window | 10,000 | 40kg |

| 6 | Window/Door | 25,000 | 40kg |

| 7 | Door | 200,000 | 40kg |

| 8 | Window | 10,000 | 60kg |

| 9 | Window/Door | 25,000 | 60kg |

| 10 | Door | 200,000 | 60kg |

| 11 | Door | 200,000 | 80kg |

| 12 | Door | 200,000 | 100kg |

| 13 | Door | 200,000 | 120kg |

| 14 | Door | 200,000 | 160kg |